Joining Dissimilar Aluminium Alloys by Resistance Spot Welding for Aluminium- Intensive Mixed Constructions

Autoren: M. Sc. Maike Epperlein, Dr.-Ing. Alexander Schiebahn, Prof. Dr.-Ing. Uwe Reisgen

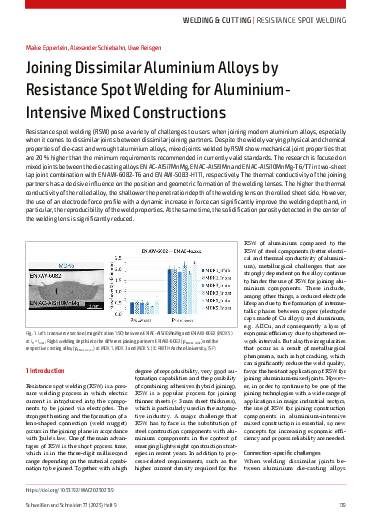

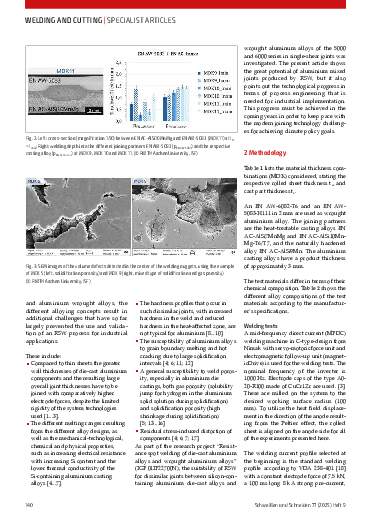

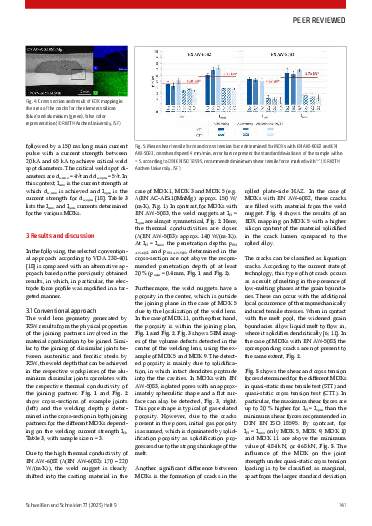

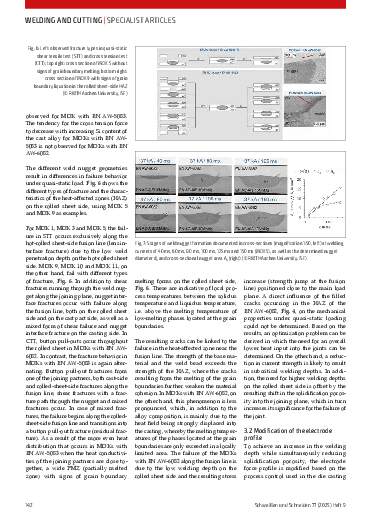

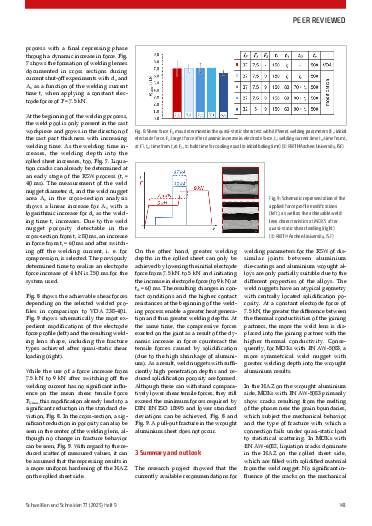

Resistance spot welding (RSW) pose a variety of challenges to users when joining modern aluminium alloys, especially when it comes to dissimilar joints between dissimilar joining partners. Despite the widely varying physical and chemical properties of die-cast and wrought aluminium alloys, mixed joints welded by RSW show mechanical joint properties that are 20 % higher than the minimum requirements recommended in currently valid standards. The research is focused on mixed joints between the die casting alloys EN AC-AlSi7MnMg, EN AC-AlSi9Mn and EN AC-AlSi10MnMg-T6/T7 in two-sheet lap joint combination with EN AW-6082-T6 and EN AW-5083-H111, respectively. The thermal conductivity of the joining partners has a decisive influence on the position and geometric formation of the welding lenses. The higher the thermal conductivity of the rolled alloy, the shallower the penetration depth of the welding lens on the rolled sheet side. However, the use of an electrode force profile with a dynamic increase in force can significantly improve the welding depth and, in particular, the reproducibility of the weld properties. At the same time, the solidification porosity detected in the center of the welding lens is significantly reduced.

Als Abonnent haben Sie die Möglichkeit einzelne Artikel oder vollständige Ausgaben als PDF-Datei herunterzuladen. Sollten Sie bereits Abonnent sein, loggen Sie sich bitte ein. Mehr Informationen zum Abonnement